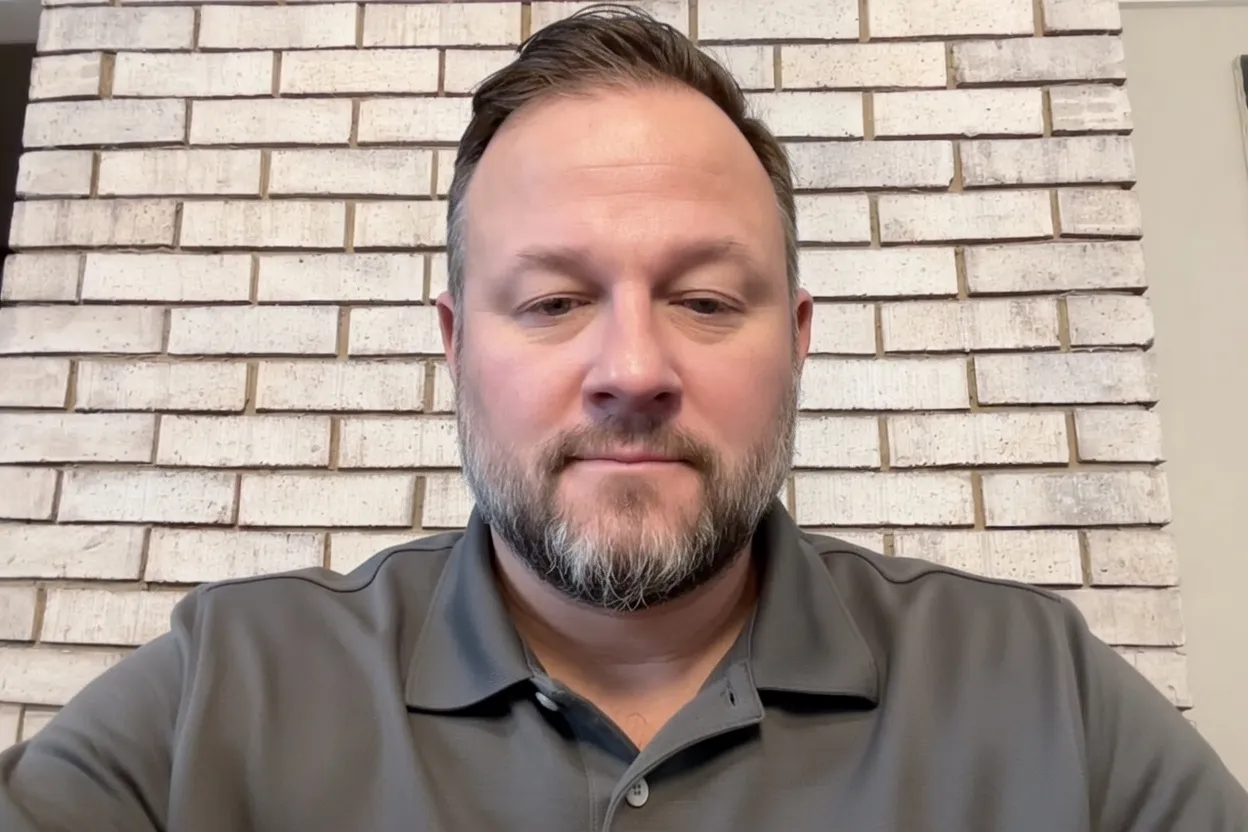

"I've made the mistakes so you don't have to."

I run a metal fabrication shop in Wisconsin, so I understand firsthand how small manufacturers operate. The quoting pressure, scattered job tracking, constant interruptions, and paperwork that steals time from production. Most shops are not broken. They are overloaded and under-supported by the tools available to them.

I also bring 15+ years of software development experience. That combination lets me approach shop problems differently, not as a consultant selling software, but as an operator who understands the floor and knows how to build practical systems to support it.